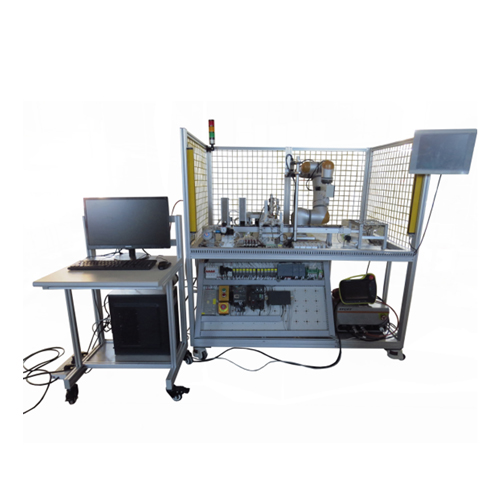

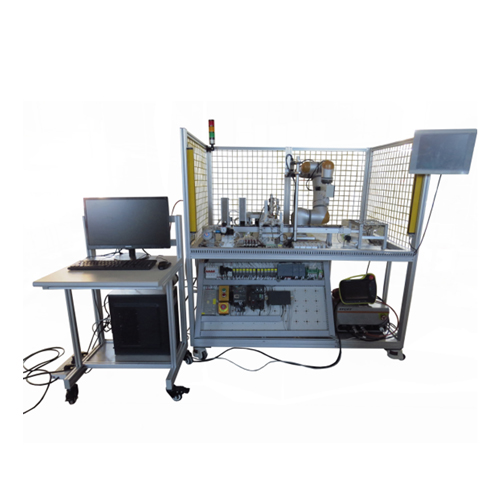

MR107M Collaborative 6-axes Robot Arm With Camera And Gripper Teaching Equipment Educational Mechatronics Training Equipment

Demo, robot programming, high-tech vocational training equipment. Working radius: 500 mm Carrying load: 3 kg Repeatability: +/- 0.1 mm Control operation: 12-inch touch screen with user-friendly graphic design interface

Degrees of freedom: 6 rotating joints

I/O interface: 16 DI, 16 DO, 2 AI, 2 AO

Electric gripper: adjustable gripping force 3 N, max. 40 N, stroke max. 110 mm

Camera system: Maximum resolution: 5 Mpx (2560 x 1920), maximum image frequency: 30 fps

1. Product Overview

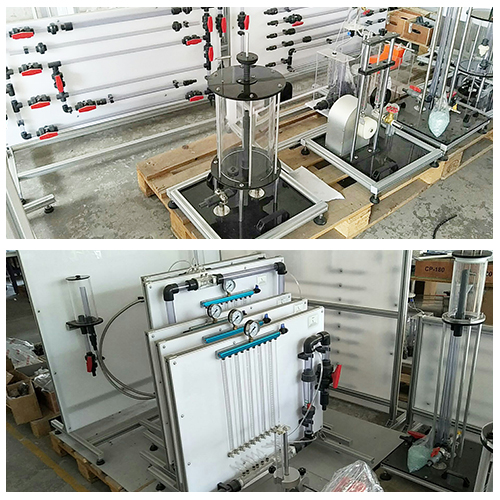

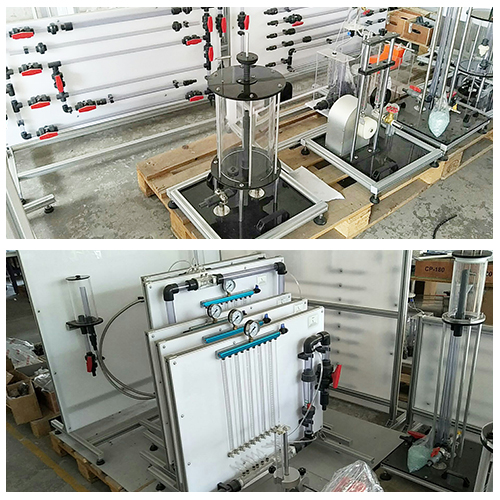

This equipment takes industrial robots and machine vision as the core, organically integrates mechanical, pneumatic, motion control, frequency conversion speed regulation, PLC control technology, modular structure, easy to combine, to achieve rapid detection and assembly of different materials. In order to facilitate practical training and teaching, the system has been specially designed to complete various types of robot individual training and comprehensive project training, and to complete various types of robot individual training and comprehensive project training. Six-axis robot teaching, positioning, grasping, assembly, storage and other training can be carried out,

It includes six-degree-of-freedom industrial robots, intelligent visual inspection systems, PLC control systems, and a set of feeding, conveying, assembling, and warehousing mechanisms, which can implement operations such as sorting, testing, handling, assembly, and storage of workpieces.

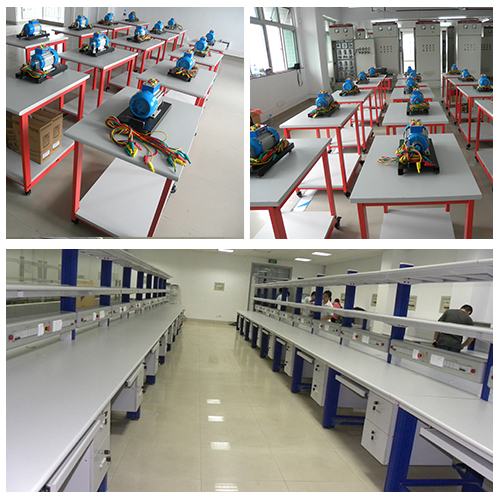

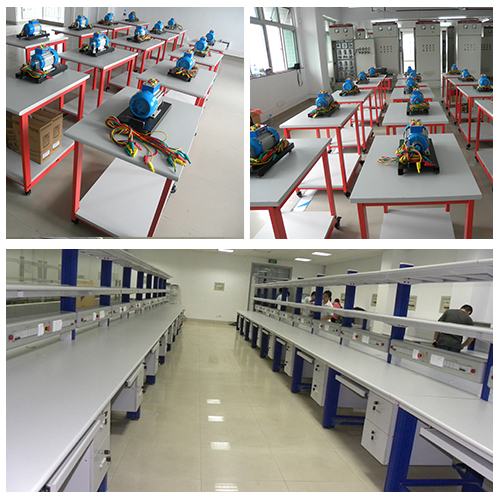

The components of the platform are all installed on the profile table. The mechanical structure, electrical control circuit and actuator are relatively independent, and are designed with industrial standard parts. Through this platform, it can be trained in various aspects such as mechanical assembly, electrical circuit design and wiring, PLC programming and debugging, intelligent visual process editing, industrial robot programming and debugging applications, and is suitable for vocational colleges and technical school automation related majors. The practical training of courses such as "Control Technology" and "Automation Technology" are suitable for automation technicians to conduct engineering training and skill competitions.

2. Technical performance

1. Input power: single phase~220V±10% 50Hz

2. Working environment: temperature -10℃~+40℃, relative humidity ≤85% (25℃), altitude <4000m

3. Device capacity: <1.5kVA

4. The size of the training platform: 1500mm×880mm×1400mm

5. Safety protection: with leakage protection, safety meets national standards

3. Equipment structure and composition

The training platform consists of a six-degree-of-freedom industrial robot system, an intelligent visual inspection system, a programmable controller (PLC) system, a feed unit, a conveyor unit, a feed waste temporary storage unit, a processing waste temporary storage unit, a workpiece assembly unit, It consists of warehouse unit, various workpieces, profile training table, profile computer desk, etc.

1. Six degrees of freedom industrial robot system

2. Intelligent visual inspection system

3. Siemens programmable controller unit

4. Feeding unit

5. Conveying unit

6. Workpiece assembly unit

7. Warehouse unit

8. Temporary storage of waste products

4. Practical training projects

1. Principle, use and debugging of machine vision system

2. The principle, use and debugging of the six-axis industrial robot system

3. Calibration and mutual conversion between the six-axis industrial robot coordinate system and the machine vision coordinate system

4. Installation and commissioning of integrated applications of industrial robots and machine vision systems

5. Machine vision system template setting, programming and debugging

6. Manual debugging of industrial robots through the teaching unit

7. Set and modify the coordinates of each control point through the teaching unit

8. Write and modify industrial robot programs through the teaching unit

9. Robot tracking coordinate setting

10. Software development and programming of industrial robot system